Gịnị mere efere anyị na-eyi ji enwe ezigbo ike eyi?

1. Ihe mejupụtara kemịkalụ machie bụ isi.

Isi ihe dị na efere Wodon bụ C (%): 3.0-5.0 na Cr(%): 25-40.

Nkezi kemịkalụ a na-ebute nnukwu ọnụọgụ nke Cr7C3 chrome carbide particles siri ike. Micro hardness (ruo HV1800)nke ndị aahụ dum oyi akwa ga-ekwe nkwa a ibu iyi na-eguzogide elu.

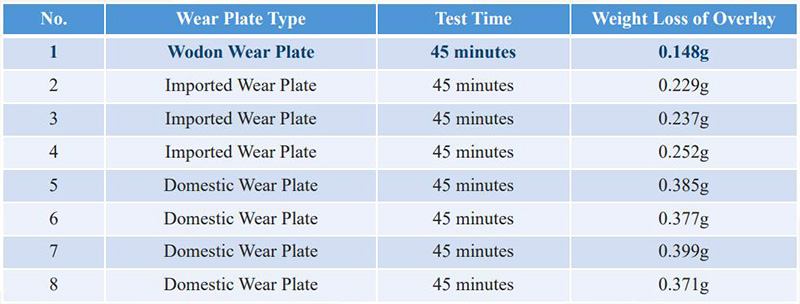

Nnwale arụmọrụ:

Ngwa ule: wheel rubber ájá quartzigwe nyocha abrasion.

Ọnọdụ: 1. Ịhọrọ otu ụdị ụdị maka ihe dị iche iche na ndị na-emepụta efere, ma tinye ha.n'okpuru otu iyi uwe ọrụ na akụrụngwa nnwale anyị.

2.Nkeji 45 maka ụdị ọ bụla

Nkeji 45 maka ụdịdị ọ bụla

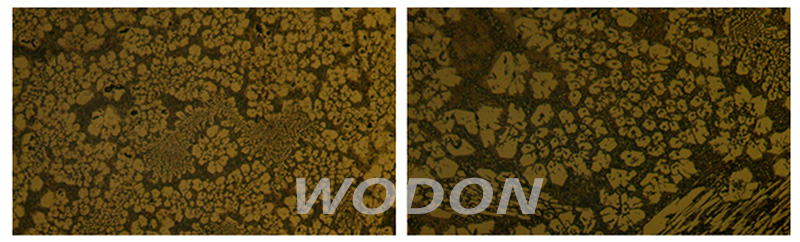

2. Chromium carbide microstructure

Nguzogide iyi nke efere eyi na-adabere n'ọtụtụ n'ime ike, ọdịdị, nha, ọnụọgụ na nkesa nke chromiumcarbide siri ike ahụ.

Dị ka ị nwere ike ịlele na foto a, akụkụ nke carbide (Cr7C3) na microstructure dị n'elu 50%.

3. Njide ike n'etiti ihe mkpuchi na isi efere.

Ihe mkpuchi na efere isi na-ejikọta nke ọma. Ihe mkpuchi ahụ ga-abanye n'ime efere isi ihe dịka 0.8mm-1.8mm, ruteruo 350Mpa na ule anyị.

Oge nzipu: Ọgọst-16-2021